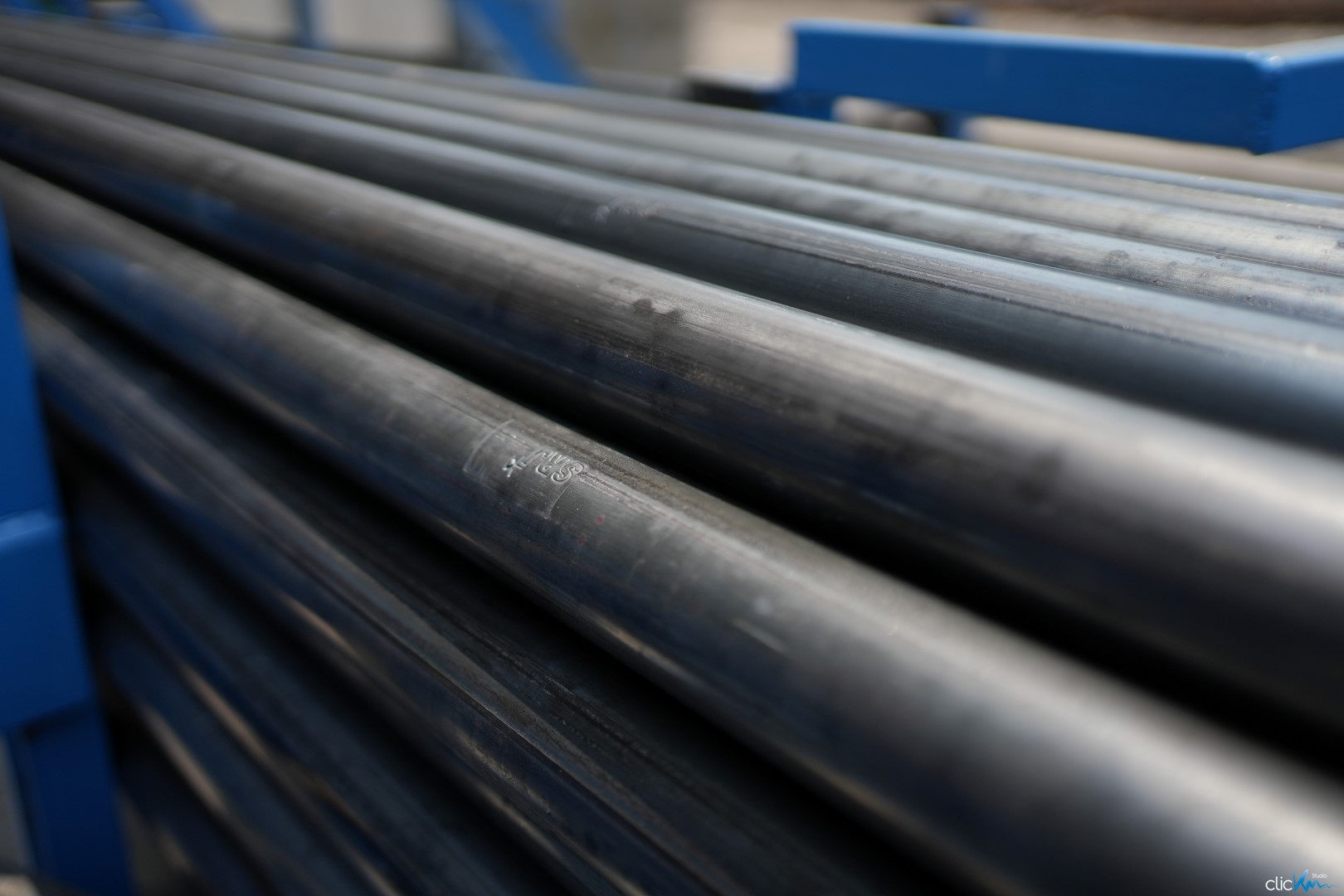

The Role of Market Demand in Steel Pipe Pricing

Market demand is a critical factor in determining the cost of steel pipes, influencing pricing in procurement, distribution, and manufacturing. When demand rises, prices tend to increase, while a drop in demand usually brings prices down. Various factors like industry growth, economic trends, and regulations can drive these changes. Additionally, supply chain elements such as raw material availability, production capacity, and logistics play a key role. Understanding these influences allows businesses to make informed decisions. Below, we explore the relationship between market demand and steel pipe costs, emphasizing important factors and their effects.

1. Basic Economic Principles

The cost of steel pipes, like any commodity, is governed by the simple rule of supply and demand. When demand rises while supply remains unchanged, prices typically go up. Conversely, when demand falls and supply stays steady, prices tend to decrease.

2. Factors Driving Market Demand

Several key factors shape the demand for steel pipes, impacting their pricing:

- Industry Growth: Demand for steel pipes is strongly linked to industries such as construction, oil and gas, automotive, and infrastructure. For example, a surge in construction projects can drive up steel pipe prices due to higher demand.

- Economic Conditions: The overall economic climate greatly affects demand. Economic expansion usually leads to increased infrastructure projects, boosting the need for steel pipes. In contrast, during recessions, demand often declines as projects get delayed or canceled.

- Technological Advances: Innovations in technology and manufacturing can alter demand. New applications or improved materials might lead to increased or reduced demand for steel pipes.

- Regulatory Changes: Government regulations, such as environmental laws or trade tariffs, also influence demand. Stricter standards may require specific types of steel pipes, affecting both demand and price.

3. Supply Chain Factors

- Raw Material Availability: The availability and cost of raw materials like iron ore and coal directly affect steel pipe production costs. When raw material prices rise, steel pipe costs generally follow.

- Production Capacity: Manufacturers’ ability to scale production in response to demand is crucial. Limited production capacity can lead to price hikes when demand outpaces supply.

- Logistics and Transportation: A well-functioning logistics network is vital for maintaining a steady supply. Disruptions, such as strikes or natural disasters, can interrupt supply chains, leading to price volatility.

Stabilizing Prices Amid Market Fluctuations

While market demand can create price fluctuations, a reliable manufacturer can help stabilize costs by implementing strategies like:

- Efficient production methods

- Strategic sourcing of raw materials

- Effective inventory management

- Technological innovations

- Strong customer relationships and risk management

These practices allow manufacturers to offer stable pricing, fostering customer trust and strengthening their competitive position in the market.

If you’re searching for trusted MS square pipe, MS tube, or steel pipe manufacturers, we provide a wide range of products, including GI pipes, ERW black pipes, and MS pipes, with thicknesses from 2 to 10 mm and outer diameters ranging from 15 to 400 mm. With over 40 years of experience, we’re dedicated to delivering quality products. Contact us to learn more about our offerings, including pricing and customization options.